HiFocus neo

HiFocus neo – efficient plasma cutting

When using the HiFocus technology for plasma cutting, a swirl gas is added which rotates around the plasma beam at very high speed and constricts the plasma beam heavily. The rotation of the swirl gas has the effect that the plasma beam is stabilised and protected. A big advantage for users is that this technology allows nearly rectangular cut surfaces within a broad range of material thicknesses.

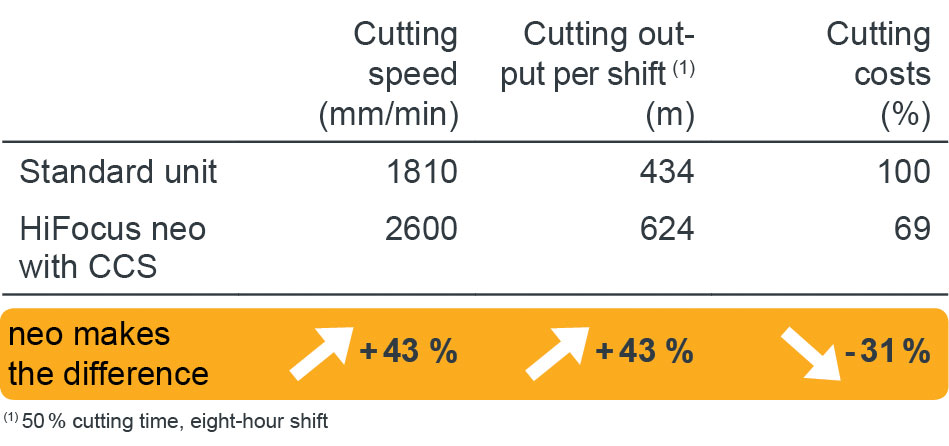

The reduction of cutting costs is illustrated by the following example calculation.

With HiFocus neo plasma cutting is more efficient:

The user benefits from high cutting speed, best quality and a wide cutting range from 0.5 to maximum 160 mm. The cutting costs are reduced due to an optimised technology protecting the consumables and thus iextending their lifetime, robust copper cathodes with an excellent price performance-ratio, a lower gas consumption compared with the competition and an increased cutting output thanks to highest cutting speed and quality with the Contour Cut technology.

neo is standard in the models HiFocus 130 neo, HiFocus 161i neo, HiFocus 280i neo, HiFocus 360i neo, HiFocus 440i neo and HiFocus 600i neo.