GMA Welding

What is Gas-Shielded Metal Arc Welding?

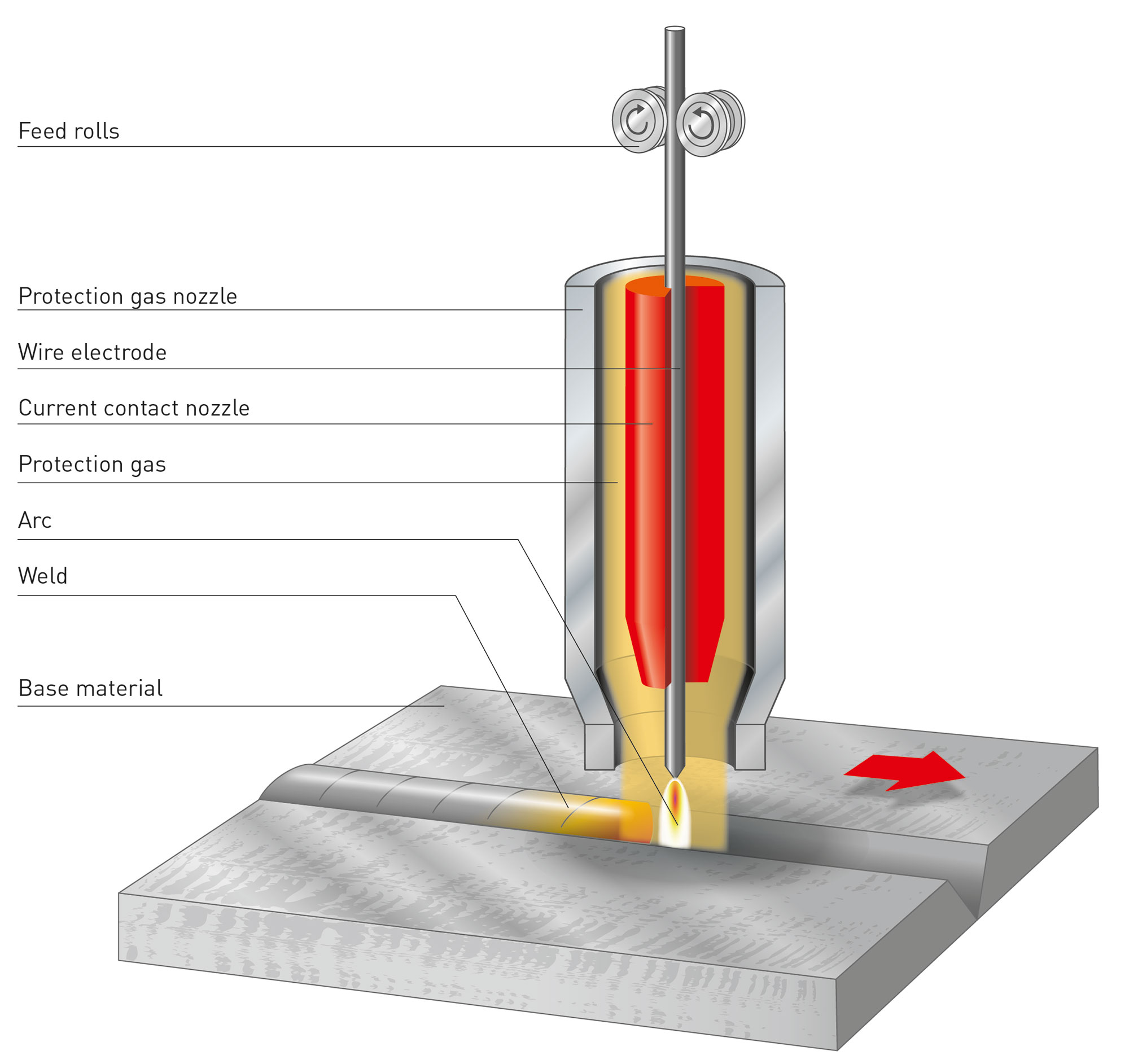

Gas-shielded metal arc welding is an arc welding process where an endless wire electrode melts under a shielding-gas cover which protects the welding zone against environmental influences. This process is characterised by high versatility with respect to the material, the degree of mechanisation and the welding position. Gas-shielded metal arc welding can be used for almost all weldable materials.

Unalloyed and alloyed steels are preferably welded with active gases, e.g. carbon dioxide. This process variety is called metal active gas welding, in short MAG welding. High-alloyed steels and materials like aluminium, magnesium, nickel-based materials and titanium are welded with inert gases, e.g. argon. The process variety used in this case is called metal inert gas welding, in short MIG welding.

Gas-shielded metal arc welding can be used for joining thin sheets with a material thickness from 0.8 mm as well as for welding thicker sheets with a material thickness of more than 10 mm. GMA welding can be used with hand-guided torches as well as with fully mechanical support systems like portals or robots.