Guiding Systems

Plasma cutting systems made by Kjellberg Finsterwalde can be combined with a wide variety of 2D and 3D guiding systems. They are used in combination with cutting tables or also pipe cutting machines in steel and stainless steel service centres as well as with robots in the automotive industry. Simple guiding systems are also widely applied in small companies.

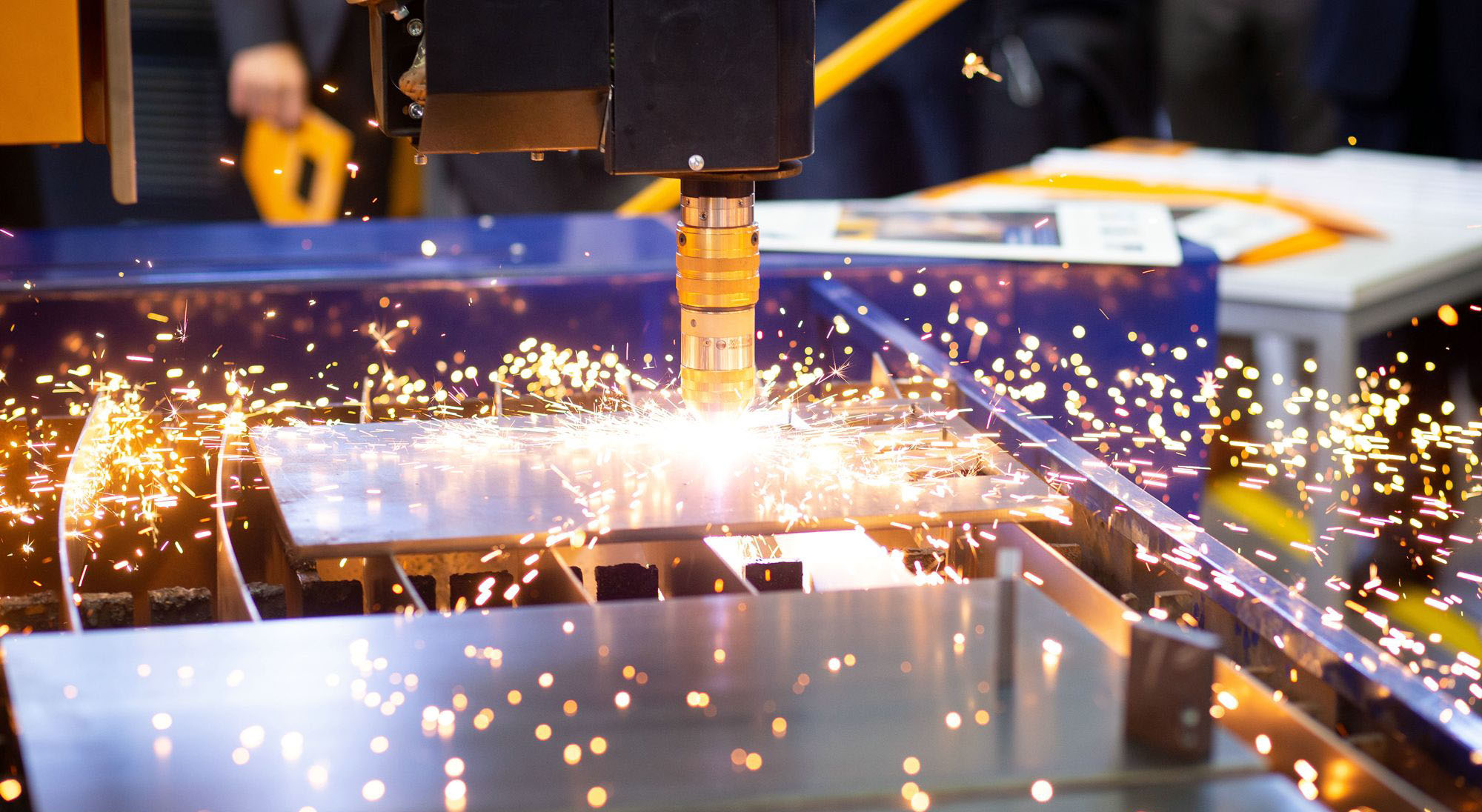

Cutting tables (also referred to as gas cutting machines) are most frequently used in the industry and are ideally suited for CNC-guided 2D and increasingly also for 3D cutting tasks. These systems allow an excellent cut quality combined with high contour and dimensional accuracy and above all high cutting speeds. The latter are the foundation for an efficient production, also with regard to environmental as well as occupational health and safety aspects. Furthermore, Kjellberg Finsterwalde offers a wide range of additional components which can be connected to the cutting tables. In addition to different types of height control units which are imperative for high-quality cut results, it is possible to use the automatic torch head quick-change unit ATChanger in combination with CNC-controlled systems. Moreover, the manufacturers of cutting tables as Kjellberg Finsterwalde's partners provide manifold solutions to offer you additional components like for example rotating heads for bevel cutting. Thus, the way is free for highly precise weld preparation with angles of up to 60°.

Pipe cutting machines are especially designed for cutting pipes (or also profiles). With a special support the pipe can be turned so that the optimum cutting position is always guaranteed. In addition to a fixed torch holder, other options are also often used, i.e. combining the plasma torch with a bevel cutting head, a robot or other 3D kinematics for weld preparation.

Industrial robots and other automated systems are excellently suited for economic large-scale and low-volume production as well as piece production. Robots can be freely programmed with regard to motion sequences. With their complex sensor technology they are ideally suited for cutting three-dimensional work-pieces in various areas, such as in the automotive industry, container and pipeline construction, shipbuilding and foundries.

With robots numerous advantages are achieved which in total contribute to a flexible and economic production: cutting of strongly varying material grades and thicknesses and of complex three-dimensional contours, easy programming and operation, high cutting speeds, nearly no rework required as well as various further possible applications like plasma marking, bevel cutting, underwater plasma cutting, cutting of interrupted structures (Hotwire) and cutting of hot work-pieces.

Plasma cutting systems from the Q-Series and HiFocus series can be used with all standard robots and robot controls. All electrically conductive materials, even complex parts with unusual shapes, can be shapes, can be cut precisely.

Torches especially designed for robot applications as straight version or with angled torch head also cut strongly structured work-pieces: PerCut 160-2 60° LS with torch head that is angled by 60°, PerCut 211 M as straight version, PerCut 451 M as straight version, PerCut 611 M as straight version.

More information: Robot-guided plasma cutting

In addition to big CNC-guided gas cutting machines for complex cutting tasks, there are guiding systems that are appropriate for simple applications and smaller budgets. Here too, the plasma cutting machine and the guiding system are matched to one another, but normally they do not allow high-quality cuts. Furthermore, plasma torches (also hand plasma torches) can be used efficiently in connection with simple linear axes, circle cutting devices and other manually or automatically (electrically) guided systems.